Schaeffler at EMO 2025 (Hall 6, Booth I46) Rolling bearings and linear technology for the megatrends in the machine tool industry

2025-09-10 | Schweinfurt

- New PTB series precision angular contact ball bearings for driven tools

- Hybrid screw drive bearings provide a solution for short-stroke applications

- New KLLT series linear ball bearing and guideway assemblies for machine tool peripherals, handling axes, and assembly axes

For decades, Schaeffler – the Motion Technology Company – has been developing innovative precision rolling bearings and drive systems for leading machine tool manufacturers. Key components include linear guidance systems and linear motors for main axes, precision bearings for main spindles, as well as rotary table bearings and torque motors for rotary tables, milling heads, and portal milling machines. The industry’s megatrends – automation and multi-process machining – are having a direct impact on the development of new machine axes, and therefore on the rolling bearings and drive systems themselves.

Christian Straub, Manager Sector Development Industrial Automation, explains: “For machine tool automation, we are now developing a dedicated class of rotary table bearings – streamlined to the essentials, with low-maintenance operation, tailored stiffness, and designed for lower speeds.”

For spindle bearings and rotary tables in multi-process machines, however, the requirements are quite the opposite. “Here, higher speeds and stiffness are required, which we achieve with high-end components such as spindle bearings made of the high-performance rolling bearing steel Vacrodur, and YRTS series bearings for turn-milling tables,” adds Straub.

New precision bearings for driven tools

Committed to offering rolling bearings for all axes, Schaeffler will be showcasing new precision angular contact ball bearings for driven tools at EMO in Hanover. The PTB (Precision Tool Bearings) series has been newly developed as a cost-efficient solution for both original equipment and the reconditioning of driven tools.

New hybrid bearings to counteract false brinelling

In addition to the double-row screw drive bearings ZKLN-HC and ZKLF-HC (with flange mounting), Schaeffler’s portfolio now also includes the three-row DKLFA screw drive bearings with ceramic rolling elements. These hybrid bearings provide a reliable solution to prevent false brinelling on the raceways. This damage pattern typically occurs in short-stroke applications, where small oscillating movements displace the lubricant from the rolling contact.

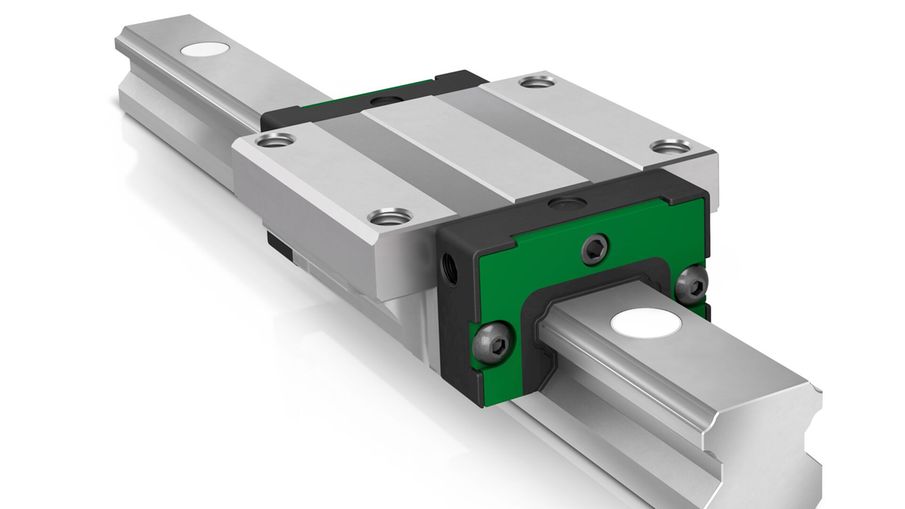

New series of linear recirculating ball bearing and guideway assemblies

In the linear technology sector, Schaeffler is expanding its range of monorail guidance systems to include the newly developed KLLT series of four-row linear recirculating ball bearing and guideway assemblies, designed specifically for applications in production machinery peripherals and, in particular, for lighter handling systems.

The defining feature of this series is its X-arrangement, which allows the assemblies to mate more effectively with substructures that have minor shape errors, without generating significant constraining forces.

Rotary table bearings developed specifically for automation

For axes outside the machining area, such as pallet changers, Schaeffler is showcasing the new YRTA rotary table bearing series at EMO. Bearings in this series have been designed specifically for the requirements of highly rigid “automation axes.” A particularly innovative option is the YRTAG design, in which a customer-specific gear toothing is integrated into the inner ring of the bearing. This enables manufacturers to save valuable installation space, reduce weight, and, above all, shorten assembly time.

Frequently overlooked: lubricants can significantly extend service life

In both the development and operation of production machinery, lubricants are sometimes not given the attention they deserve. Yet the quality differences between lubricants are considerable. Using the right lubricant can greatly increase the service life of both rotary and linear rolling bearings, as demonstrated by Schaeffler’s Arcanol lubricant test results.

At Schaeffler’s booth I46 in Hall 6, visitors can learn more about the various tests used to qualify lubricants, as well as the services offered by Schaeffler’s application engineers, lubrication specialists, and test engineers.

Publisher: Schaeffler Technologies AG & Co. KG, Schweinfurt

Country: Germany

Terms of use for Schaeffler press pictures

Schaeffler press pictures may only be used for editorial purposes. Unless otherwise stated, all copyrights and rights of use and exploitation are owned by Schaeffler Technologies AG & Co. KG, Herzogenaurach (Germany) or by one of its affiliated companies. The reproduction and publication of Schaeffler press pictures is only permitted if the source is stated as follows: "Image: Schaeffler". The pictures may be used free of charge in such cases. The use of pictures for advertising or other commercial purposes, in particular their disclosure to third parties for commercial purposes, is hereby prohibited. Pictures may only be edited with the approval of Schaeffler.

We kindly request that a specimen copy be sent to us when Schaeffler press pictures are published in printed media (or a digital copy in the case of publication in electronic media). When using Schaeffler press pictures in films, please notify us and state the title of the film.

Use and utilization of Schaeffler press pictures is subject to the substantive laws of Germany without its conflict of law provisions. The place of competent jurisdiction shall be Nuremberg, Germany.

Postal address:

Schaeffler Technologies AG & Co. KG

Corporate Communication

Industriestrasse 1-3

91074 Herzogenaurach

Germany

Press releases

Package (Press release + media)