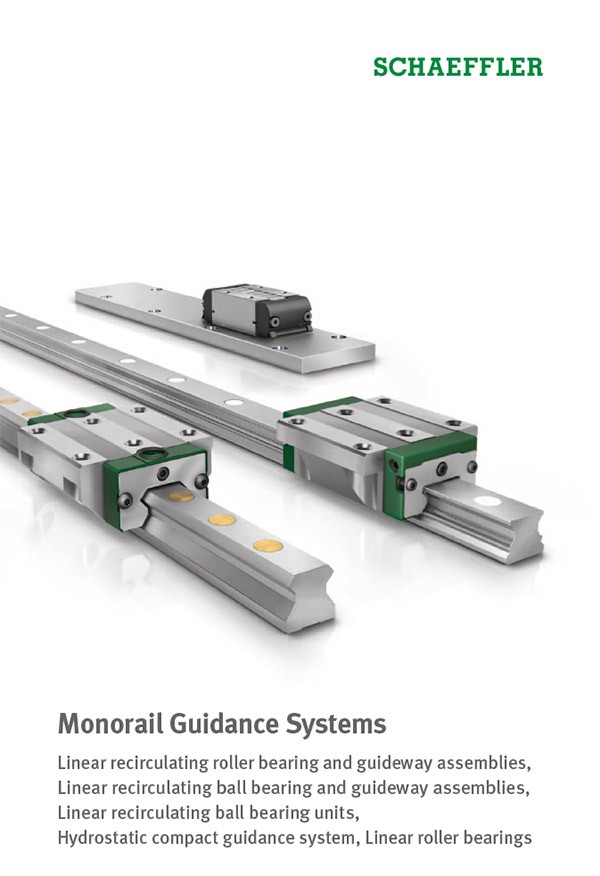

Schaeffler INA Monorail Guidance Systems

All About Linear Motion Systems

Linear motion is a one-dimensional motion along a straight line, and thus the linear motion bearing or slide concept is evolves that provide free motion in one dimension. The linear motion is supported by Linear Guidance Systems that consist of blocks and rails that help support the motion in all applications. These systems are very common in measurement applications, optical industry and electronic industry where mechanical systems are required for special purposes.

Schaeffler offers ready-to-fit with precise specification INA Monorail Guidance System for applications with long, unlimited stroke length, high-load carrying capacity and rigidity with high running and positional accuracy as well as low friction.

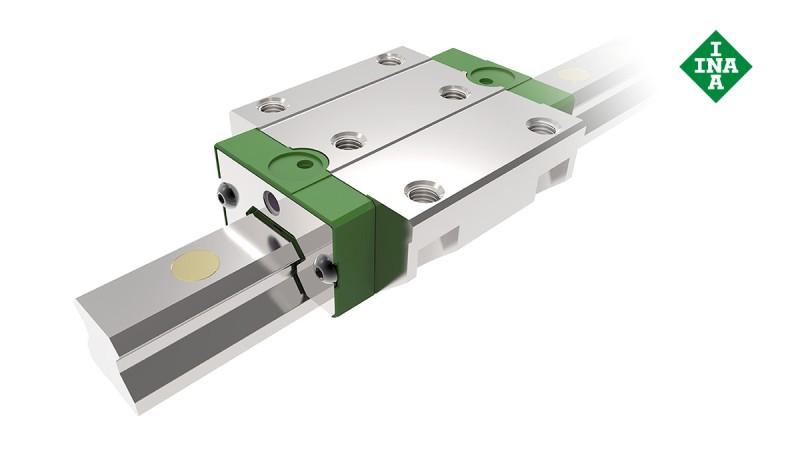

Compact and Complete Linear Guidance Systems Having High Rigidity and Load Carrying Capacity

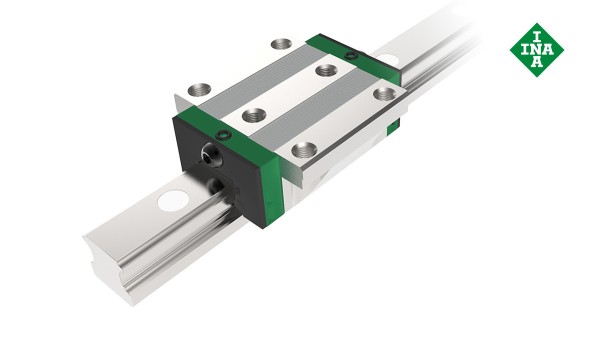

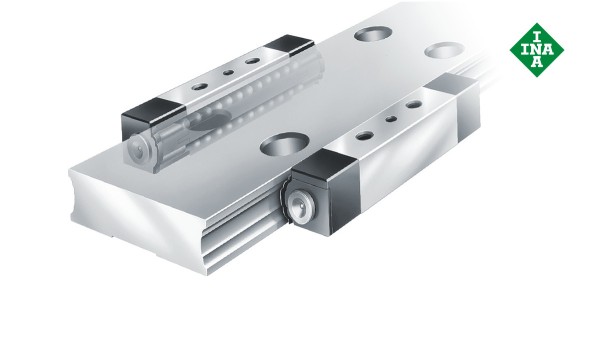

INA Monorail Guidance Systems are compact linear guidance systems that are supplied as standard with high rigidity and load carrying capacity as a complete package. They can support forces from all directions, apart from the direction of motion, as well as movements about all axis. It can be supplied in various accuracies and preload classes. As a result, they are also suitable for applications with high guidance and positioning requirements.

In most series, the carriages and guideways can be used in any combination within the same accuracy class. This gives a high degree of design flexibility with simplified fitting and reduced stockholding costs. In order to reduce maintenance costs, the linear recirculating ball bearing and guideway assemblies have a lubricant reservoir. As a result, they are low-maintenance for many applications.

Various Types of INA Monorial Guidance Systems

Applications That Use Monorial Guidance System

Wide range of applications include Printing Machinery, Medical Equipment, Food Processing and Packaging, Textile Machinery, Machine Tools, Woodworking Machinary, Rubber and Plastics, Assembly and Parts Handling, Industrial Robots and Power Tools, Productronics.

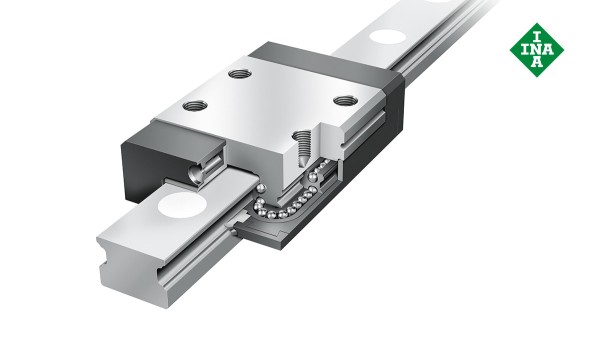

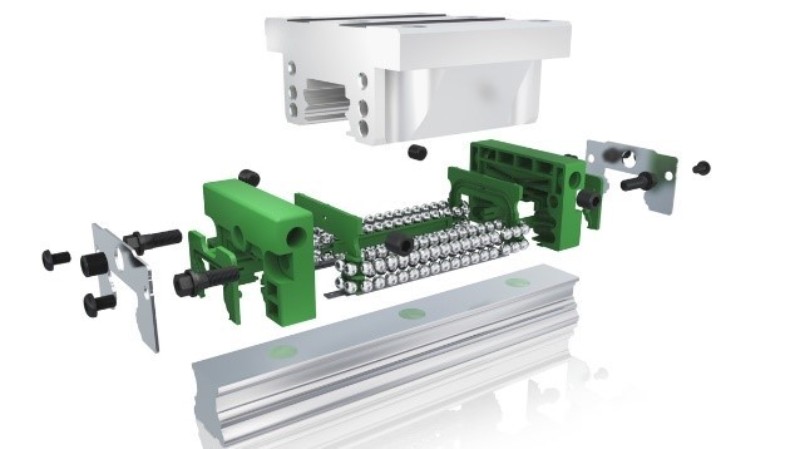

Components Of Linear Guideway Assembly

- Carriages

- Stainless steel strip

- Magnets

- End cap anchors

- End seal

- Return guides

- Rail

- Grease Fitting

Customization and Supply in Just 1/10th Time at Quick Center in India

Schaeffler now offers ready-to-fit customized linear guides solution as per customer application need in no time. Introducing Quick Center in India where the products are customized and made ready to supply to customers in less stipulated time.

Advantages Of Linear Guideways

- High positional accuracy

- Long life with highly accurate motion

- Attains high speed motion with less driving force

- Equal loading capacity in all directions

- Easy installation

- Easy lubrication

- Interchangeability

Do You Have Any Questions About Our Products?

We want to ensure that you receive fast, expert answers to your questions about our product portfolio. By using the form below, your question will be sent directly to our experts at Schaeffler India. Our engineers will then contact you.