INA Needle Roller Bearings by Schaeffler

Stronger, Smoother and Quieter Bearing Solutions

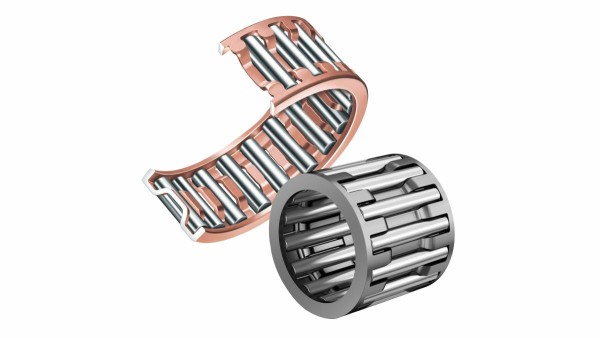

Needle roller bearings have a long track record as proven machine elements for the design of radially compact bearing arrangements with very high load-carrying capacity. Schaeffler's INA brand's needle roller bearings, with substantially improved load ratings, offers higher performance, longer service life, reduced friction and lower bearing temperatures. The result is greater efficiency for your applications and an unbeatable price-to-performance ratio.

Value Added Solutions

- German engineering, world class quality made in India

- Smoother transmission, powerful performance

- Reduced noise and increased durability

- Improved lifetime, reduced maintenance cost

- Reduced friction and lower oil demand

- Reduced CO2 emission through innovative engine components

Types of Needle Roller Bearings

Designed For Radially Compact Bearing Arrangements With Very High Load-Carrying Capacity, Delivering Upto 50% Longer Service Life

NRB Solutions for 2-Wheeler and 3-Wheeler Engine Applications

Our range of Needle Roller Bearings provide quality, operational reliability, and a high load carrying capacity for high speed applications in 2 wheelers and 3 wheelers. The bearings are used across a wide range of engine components, such as connecting rods, hubs, crankcase, CVT, starter gear.

Do you have any questions about our products?

We want to ensure that you receive fast, expert answers to your questions about our product portfolio. By using the form below, your question will be sent directly to our experts at Schaeffler India. Our engineers will then contact you.